Welcome to another post of my blog, Cardboard Conversation. This is an opinion post based on recent personal experience in a high volume plant, so always up for banter….

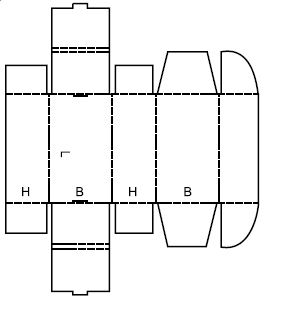

One of the most common styles of cardboard box in e-Commerce is the FEFCO 0427. Its a reasonably good protective pack and presents a good impression when the consumer opens it.

Its been around for decades at least since the 1940’s ( I’ve done my research, some would say I’ve been around that long too!).

However, there are a few draw backs. It creates a lot of stripping which doesn’t really make it very Rotary Die Cut friendly, particularly around the lid area. Often its not the greatest deckler either. To maximise the Die Cut area it sometimes has to go 4 up 2 x 2. This in itself causes crews a bit of a headache stripping wise and a bad deckle.

That’s not all. There are other FEFCO designs or even bespoke ones which use up to 25% less board. You can even run them side by side, often 1 x 5 or 1x 6 up so get more per feed rotation and a lot less stripping.

I’m sure 25% less board means a selling and commercial opportunity to enhance margins. Also bear in mind the waste area around the lid can be as much as 10% of the blank area. This is customer paid waste which they dont recieve..

So when you are starting a project don’t always go for the most obvious and popular style.

Throughput is King as a KPI for most box plants today, so your Design teams need to consider other options style wise. You have the chance to gain more margin and greater throughput with less stripping.

Now, I’m not going to say here what those styles are but I’d be happy to share them in a conversation offline.

Recent Comments